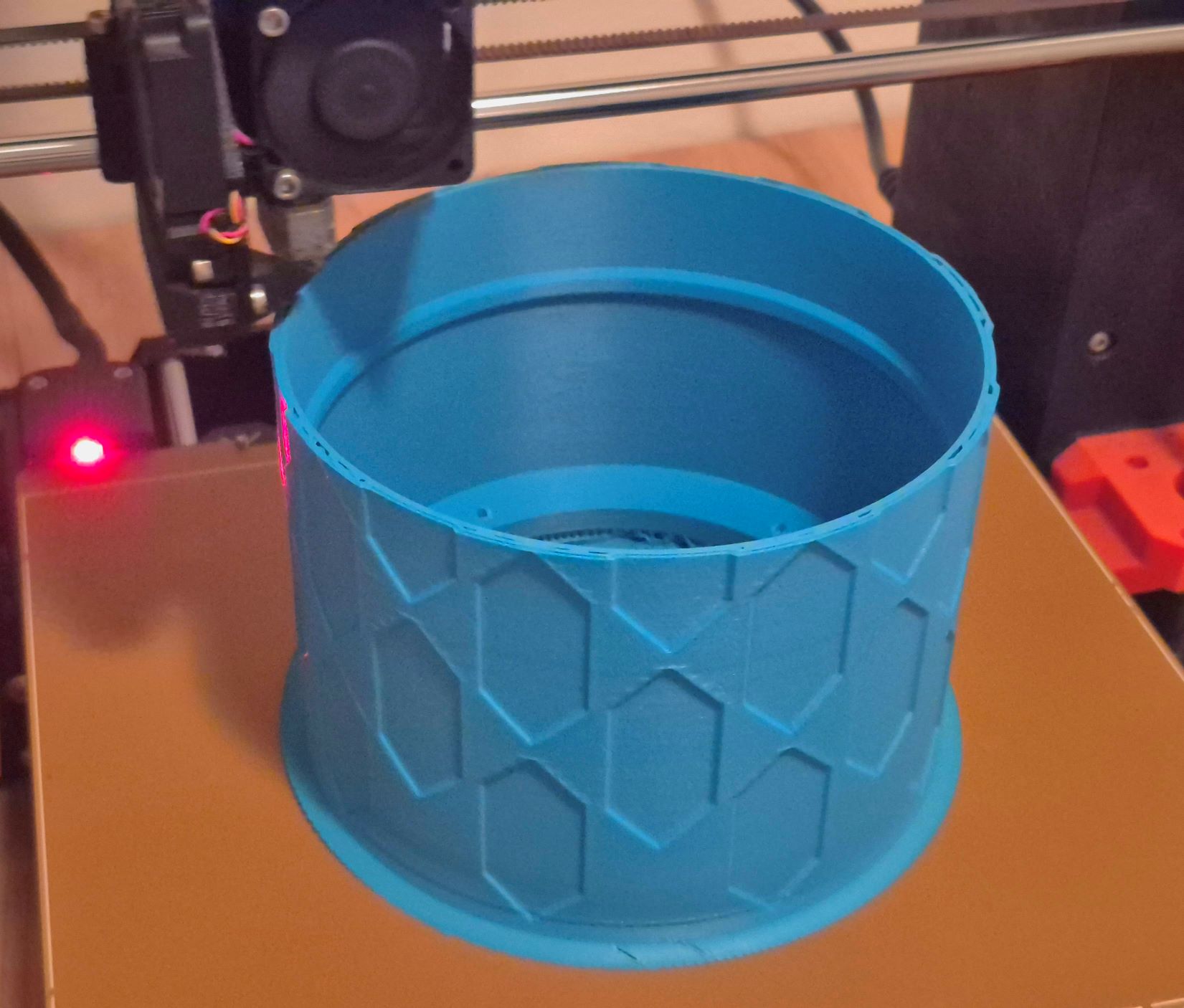

Did you know that your ELO 1 mower contains 43 different components that are produced using 3D printing?

Additive manufacturing—better known as 3D printing—is not just a buzzword. At ELO, we use it every day in production and development. Thanks to 3D printing, we can quickly produce not only prototypes, but also final parts and fixtures that are part of every ELO 1.

Why 3D printing?

-

Speed and flexibility – we can design and print a new part in hours, not weeks.

-

Lightweight and durable – thanks to modern filaments, we combine low weight with high strength.

-

Environmentally friendly – we only print as much material as we really need, without unnecessary waste.

43 components from 3D printers

You may be surprised how many parts of the ELO 1 come from additive manufacturing. In each machine, you will find:

-

10 parts made of polypropylene (PP) – a durable material with high toughness, ideal for mechanically stressed parts.

-

32 parts made of PET-G – a versatile and strong filament that combines flexibility and stability, often used for holders and structural elements.

-

1 part made of transparent PET-G – we use it where transparency and visual inspection are required.

This includes, for example, various covers, spacers, mounting fixtures, electronics holders, and ergonomic handlebar accessories.

Advantage for the customer

The use of 3D printing means that ELO 1 is not a static product. We can continuously improve and innovate parts and respond flexibly to customer experience. As a result, ELO 1 is constantly moving forward – towards better ergonomics, reliability, and user comfort.

The future is additive

For us at ELO, 3D printing is a symbol of innovation. It is not only a tool for development, but also proof that modern technology can directly improve the quality and availability of the products you use at home in your garden.

The ELO 1 is not just a lawn mower. It is also an example of how additive manufacturing is changing the world around us – from industry to your lawn.